Understand measurement system analysis principles, including comparing Gauge R&R to the EMP (Evaluating the Measurement Process) approach described by Don Wheeler in the book EMP III –Using Imperfect Data (2006). Use the attached data to use to practice using some of the techniques presented. The data, updated regularly, is also found at goldensnowball.com.

See how to:

- Quantify measurement system variation and how it impacts your process

- Understand basic measurement system evaluation principles

- Understand purposes and types of Gauge Studies

- Understand considerations for conducting a Gauge Study: Random part order, time of day, operator confidentiality, following standard procedures, monitoring but not interfering with tests

- Perform Continuous Gauge Study

- Interpret Variability Gauge Chart, Gauge R&R Measurements, Variance Components for Gauge R&R

- Run Crossed Tests

- Select tolerance intervals or specifications (LSL and USL)

- Perform Attribute Gauge Study

- Interpret Gauge Attribute Chart, Agreement Reports

- Use EMP method to achieve an interclass correlation perspective for classifying a measurement system

- Interpret Range Charts, Parallel Plots, EMP Results, Gauge Classification

- Understand purpose of Process Screening: To determine if process is steady, stable and predictable so you can use it to monitor future performance and/or evaluate impact of changes on the process

- Examine Voice of Process: Is process in control and exhibiting minimal variance?

- Examine Voice of Customer: Is process yielding good/best parts that are within specification?

- Use Control Chart Builder to examine process capability

- Interpret Individual and Moving Range Charts, Limit Summaries, XBar and R Charts, Process Capability Analysis

- Understand purpose of Multivariate Control Charts introduced in JMP 15: To identify two or more interrelated process variables where the interrelation might impact process capability although the individual processes might appear in control

Resources

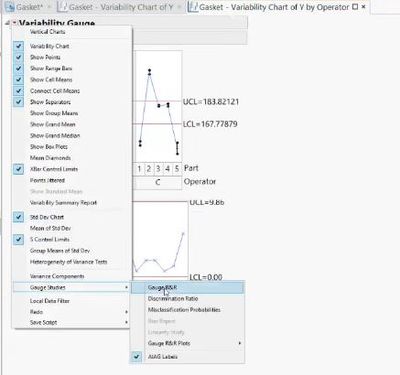

JMP Variability Gauge Study Options

JMP Variability Gauge Study Options

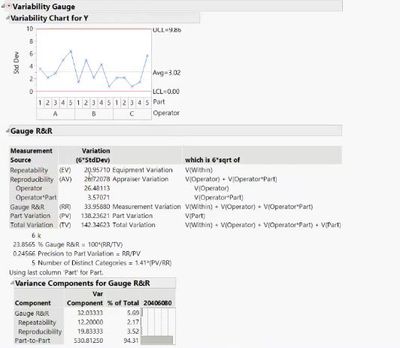

JMP Variability Gauge Study Results

JMP Variability Gauge Study Results

JMP Gauge Study Results

JMP Gauge Study Results