|

•

|

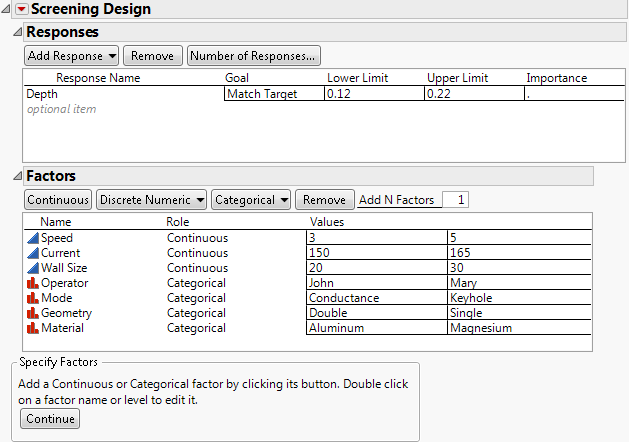

Operator is the technician operating the welding machine. Two technicians typically operate the machine.

|

|

•

|

Speed (in rpm) is the speed at which the part rotates under the beam.

|

|

•

|

Current (in amps) is a current that affects the intensity of the beam.

|

|

•

|

Mode is the welding method used.

|

|

•

|

Wall Size (in mm) is the thickness of the part wall.

|

|

•

|

Geometry indicates whether the joint is a single-bevel joint or a double-bevel joint.

|

|

•

|

Material is the type of material being welded.

|

Notice that three of these factors are continuous: Speed, Current, and Wall Size. Four are categorical: Operator, Mode, Geometry, and Material. Each of these categorical factors has two levels.

|

1.

|

Select DOE > Classical > Screening Design.

|

|

2.

|

|

3.

|

Click on the default Goal of Maximize and change it to Match Target.

|

|

4.

|

Click under Lower Limit and type 0.12.

|

|

5.

|

Click under Upper Limit and type 0.22.

|

|

6.

|

Leave the area under Importance blank.

|

The completed Responses outline appears in Figure 8.2. Now, specify the factors.

|

•

|

To enter the factors automatically, use the Weld Factors.jmp data table:

|

|

1.

|

|

2.

|

|

1.

|

|

2.

|

|

a.

|

Change the Speed values to 3 and 5.

|

|

b.

|

|

c.

|

|

4.

|

|

5.

|

|

a.

|

Change the Operator values to John and Mary.

|

|

b.

|

|

c.

|

|

d.

|

|

1.

|

Click Continue.

|

|

2.

|

(Optional) From the Screening Design red triangle menu, select Set Random Seed, type 12345, and click OK.

|

|

3.

|

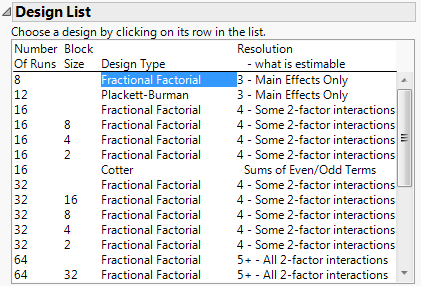

Accept the default selection to Choose from a list of fractional factorial designs and click Continue.

|

This specifies an eight-run Resolution 3 fractional factorial design. For information about resolution, see Resolution as a Measure of Confounding.

|

5.

|

Click Continue.

|

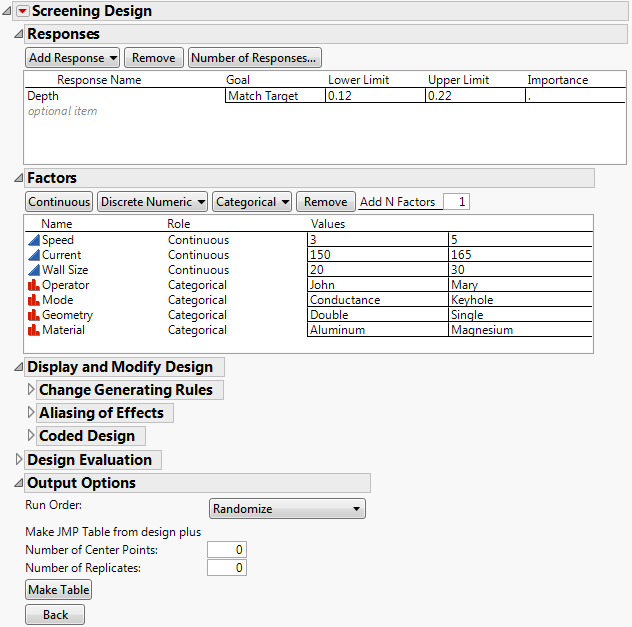

In the Output Options outline, note that Run Order is set to Randomize. This means that the design runs will appear in random order. This is the order you should use to conduct your experimental runs.

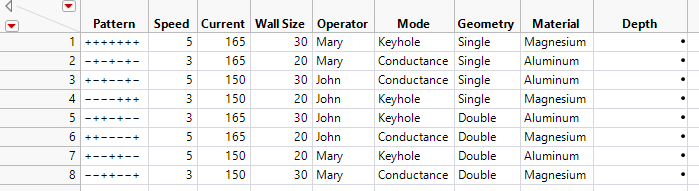

Figure 8.4 Completed Screening Design Window

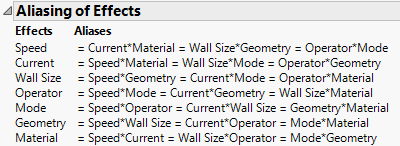

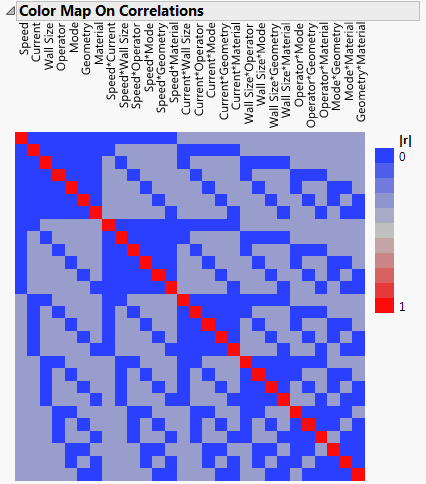

Recall that you selected a Resolution 3 design (see Figure 8.3). In a Resolution 3 design, some main effects are confounded with two-way interactions. The Aliasing of Effects outline indicates that, for this Resolution 3 design, every main effect is completely confounded with three two-way interactions. If you suspect that two-way interactions are active, this is a poor design. For a description of confounding, see Two-Level Regular Fractional Factorial.

|

7.

|

Click Make Table.

|

Figure 8.6 The Design Data Table

|

–

|

The Pattern column shows the assignment of high and low settings for the design runs.

|

|

1.

|

Open your Screening Design window. If you have closed it, then run the DOE Dialog script in the Design Data table.

|

|

2.

|

Click Back.

|

|

3.

|

Click Continue.

|

|

4.

|

(Optional) From the Screening Design red triangle menu, select Set Random Seed, type 12345, and click OK.

|

|

5.

|

(Optional) From the Screening Design red triangle menu, select Number of Starts, type 50, and click OK.

|

|

6.

|

In the Choose Screening Type panel, select the Construct a main effects screening design option.

|

|

7.

|

Click Continue.

|

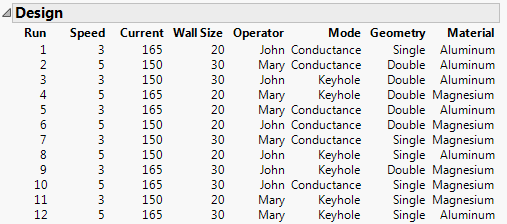

Under Number of Runs, the selected option is Default with the number of runs set to 12. Keep this setting.

|

8.

|

Click Make Design.

|

Figure 8.7 Main Effects Screening Design