You can specify computations for control limits by entering a value for k (K Sigma), or by entering a probability for α (Alpha), or by retrieving a limits value from the process columns' properties or a previously created Limits Table. Limits Tables and the Get Limits button are discussed in the section Saving and Retrieving Limits. There must be a specification of either K Sigma or Alpha. The window default for K Sigma is 3.

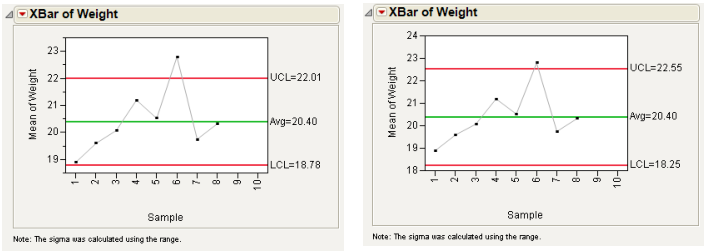

The KSigma parameter option allows specification of control limits in terms of a multiple of the sample standard error. KSigma specifies control limits at k sample standard errors above and below the expected value, which shows as the center line. To specify k, the number of sigmas, click the radio button for KSigma and enter a positive k value into the text box. The usual choice for k is 3, which is three standard deviations. The examples shown in Figure 3.6 compare the XBar-chart for the Coating.jmp data with control lines drawn with KSigma = 3 and KSigma = 4.

The Alpha parameter option specifies control limits (also called probability limits) in terms of the probability α that a single subgroup statistic exceeds its control limits, assuming that the process is in control. To specify alpha, click the Alpha radio button and enter the probability that you want. Reasonable choices for α are 0.01 or 0.001. For XBar-charts under the assumption of normality and known in-control parameters, the Alpha value equivalent to a KSigma of 3 is 0.0027.