The Reliability/CD Step Stress Pattern.jmp data table contains a column called Pattern ID that identifies four different stress patterns. The stress level at a particular step is the ratio of Voltage to Thickness. (Note that these two columns are hidden.) Thickness is held constant for each stress pattern. However, Voltage is set to different levels and increases within each pattern.

The Reliability/CD Step Stress.jmp data table contains the time to failure data.

|

1.

|

Select Help > Sample Data Library and open Reliability/CD Step Stress.jmp and Reliability/CD Step Stress Pattern.jmp.

|

|

–

|

The Time column gives the failure times.

|

|

–

|

The Pattern ID column identifies the stress pattern.

|

|

–

|

The Censor column indicates whether the failure time is exact or censored.

|

The CD Step Stress Pattern table contains the four stress patterns (identified as 1 through 4). The levels of the stress factor, Stress, are varied within each value of the Pattern ID column. The Duration column represents how many time units a particular level of the stress factor lasted.

|

2.

|

Select Analyze > Reliability and Survival > Cumulative Damage.

|

|

3.

|

Click Select Table in the Time-to-Event panel.

|

|

4.

|

The columns from this table now populate the Select Columns list in the Time-to-Event panel.

|

5.

|

|

6.

|

|

7.

|

|

8.

|

Click Select Table in the Stress Pattern panel.

|

|

9.

|

The columns from this table now populate the Select Columns list in the Stress Pattern panel.

|

10.

|

|

11.

|

|

12.

|

|

13.

|

Click OK.

|

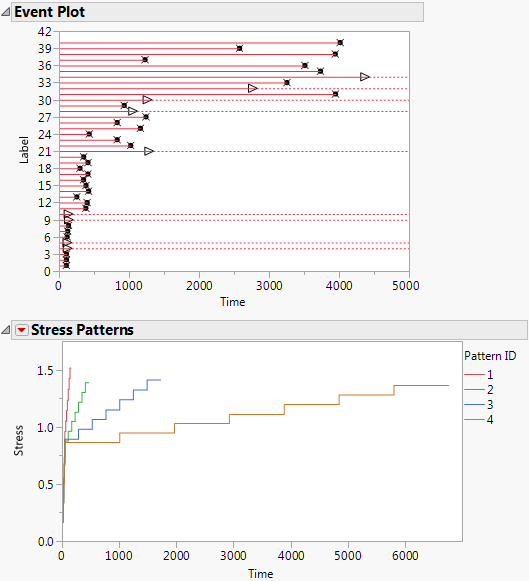

Figure 4.2 Event Plot and Stress Patterns Plot

Figure 4.2 shows the initial report that contains the Event Plot and a plot of the defined stress patterns. All four stress patterns increase the stress level quickly over the first 40 time units, after which they increase at much different rates.

|

14.

|

Select Fit All from the Cumulative Damage red triangle menu.

|

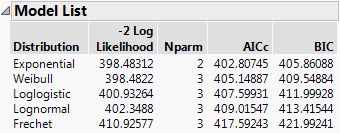

Figure 4.3 Model List Report

Figure 4.3 shows the Model List report. From this report, you determine that the best fitting distribution is the Exponential distribution.

|

16.

|

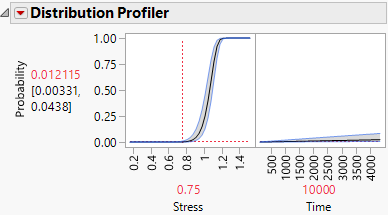

In the Distribution Profiler report, set the current value of Stress to 0.75.

|

|

17.

|

Set the current value of Time to 10000.

|

Figure 4.4 shows that the predicted probability of failure for a test unit under constant stress of 0.75 at 10000 time units is 0.007233, with a 95% confidence interval of 0.00137 to 0.03776.