|

1.

|

|

2.

|

Select Analyze > Quality and Process > Control Chart Builder.

|

|

3.

|

|

4.

|

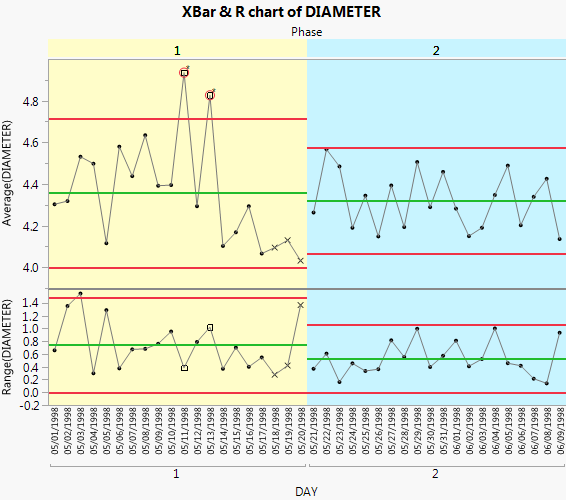

Figure 2.13 Control Charts for Diameter

|

5.

|

|

6.

|

In the Average chart, right-click and select Warnings > Test Beyond Limits.

|

Figure 2.14 Control Charts for each Phase

Including the Phase variable means that the control limits for phase 2 are based only on the data for phase 2. None of the phase 2 observations are outside the control limits. Therefore, you can conclude that the process is in control after the adjustments were made.

|

1.

|

Starting from Figure 2.14, double-click in the X axis.

|

|

2.

|

Select Allow Ranges.

|

|

3.

|

Enter -0.5 for the Min Value (the scale minimum).

|

|

4.

|

Enter 19.5 for the Max Value (the dividing line).

|

|

6.

|

Click Add.

|

|

7.

|

Click Allow Ranges.

|

|

8.

|

Enter 19.5 for the Min Value (the dividing line).

|

|

9.

|

Enter 39.5 for the Max Value (the maximum of the axis).

|

|

11.

|

Click Add.

|

|

12.

|

Click OK.

|

Figure 2.15 Diameter Phases with Color