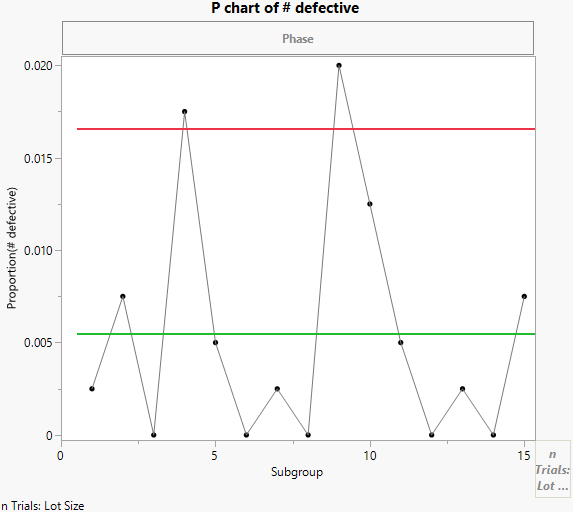

P chart Example

The Washers.jmp sample data contains defect data for two different lot sizes from the ASTM Manual on Presentation of Data and Control Chart Analysis, American Society for Testing and Materials (1976). To view the differences between constant and variable sample sizes, you can compare charts for Lot Size and Lot Size 2.

The Washers.jmp data in the Quality Control sample data folder contains defect counts of 15 lots of 400 galvanized washers. The washers were inspected for finish defects such as rough galvanization and exposed steel. If a washer contained a finish defect, it was deemed nonconforming or defective. Thus, the defect count represents how many washers were defective for each lot of size 400. Using the Washers.jmp data table, specify a sample size variable, which would allow for varying sample sizes. This data table contains all constant sample sizes.

1. Select Help > Sample Data Library and open Quality Control/Washers.jmp.

2. Select Analyze > Quality and Process > Control Chart > P Control Chart.

3. Select # defective and click Y.

4. Select Lot Size and click n Trials.

5. Click OK.

6. In the Limits outline, deselect the Show Lower Limit option.

This hides the lower limit, which is not of interest in this situation.

Figure 3.23 P chart of # defective with sample size

To view the differences between constant and variable sample sizes, you can compare charts for Lot Size and Lot Size 2 by simply dragging the variables to the nTrials zone.