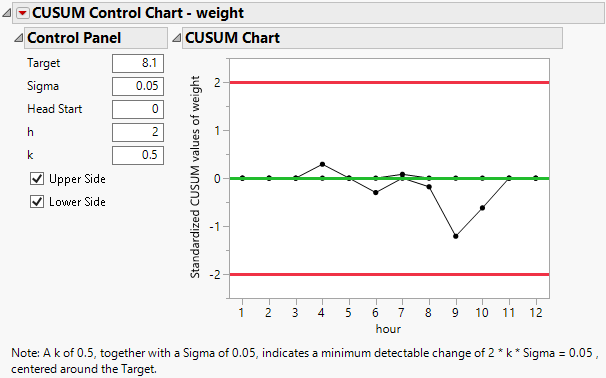

Example of CUSUM Chart with Subgroups

A machine fills 8-ounce cans of two-cycle engine oil additive. The filling process is believed to be in statistical control. The process is set so that the average weight of a filled can (μ0) is 8.10 ounces. Previous analysis shows that the standard deviation of fill weights (σ0) is 0.05 ounces.

Subgroup samples of four cans are selected and weighed every hour for twelve hours. Each observation in the Oil1 Cusum.jmp data table contains one value of weight and its associated value of hour. The observations are sorted so that the values of hour are in increasing order. You want to be able to detect a 2σ shift in the process.

1. Select Help > Sample Data Library and open Quality Control/Oil1 Cusum.jmp.

2. Select Analyze > Quality and Process > Control Chart > CUSUM Control Chart.

3. Select weight and click Y.

4. Select hour and click X.

5. Click OK.

6. In the Target box, type 8.1.

This is the target mean for the process.

7. In the Sigma box, type 0.05.

This is the known standard deviation for the process.

8. In the h box, type 2.

This defines the decision limits to be 2 standard deviations in each direction.

Figure 8.7 CUSUM Control Chart with Subgroups

The CUSUM Chart does not show any points outside of the upper or lower decision limits. There is no evidence that a shift in the process has occurred.

Note: Montgomery (2013) states that “only if there is some significant economy of scale or some other valid reason for taking samples of size greater than one should subgroups of size greater than one be used with the CUSUM.” The use of rational subgroups in the tabular CUSUM chart does not always improve the performance of the chart.