Comparison of a D-Optimal and an I-Optimal Response Surface Design

Use the Custom Design and Compare Design platforms to explore the differences between I-optimality and D-optimality in the context of a two-factor response surface design.

I-Optimal Design

1. Select DOE > Custom Design.

2. Type 2 next to Add N Factors.

3. Click Add Factor > Continuous.

4. Click Continue.

5. Click RSM.

Quadratic and interactions terms for X1 and X2 are added to the model. Because you added RSM terms, the Recommended optimality criterion changes from D-Optimal to I-Optimal. You can see this later in the Design Diagnostics section.

Note: Setting the Random Seed in the next two steps reproduces the results shown in this example. In constructing a design on your own, these steps are not necessary.

6. (Optional) Click the Custom Design red triangle, select Set Random Seed, type 123, and click OK.

7. (Optional) Click the Custom Design red triangle, select Number of Starts, type 5, and click OK.

8. Click Make Design.

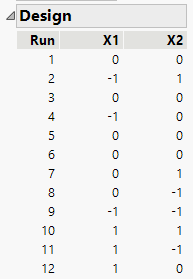

Figure 5.38 I-Optimal Design

In this I-optimal design, runs 1, 3, 5, and 6 are at the center point (X1 = 0 and X2 = 0). I-optimal designs tend to place more runs in the center (and consequently fewer runs at the extremes) of the design space than do D-optimal designs.

9. Click Make Table and then save as IOptDesign.

This data table contains your I-optimal design. Keep this table open. In the next sections, you generate a D-optimal design and then compare the two.

D-Optimal Design

To compare Prediction Variance Profile and Fraction of Design Space plots for the I- and D-optimal designs:

1. In the Custom Design window containing your I-optimal design, click Back.

Note: Setting the Random Seed and Number of Starts in the next two steps reproduces the results shown in this example. In constructing a design on your own, these steps are not necessary.

2. (Optional) Click the Custom Design red triangle, select Set Random Seed, type 123, and click OK.

3. (Optional) Click the Custom Design red triangle, select Number of Starts, type 5, and click OK.

4. Click the Custom Design red triangle and select Optimality Criterion > Make D-Optimal Design.

5. Click Make Design.

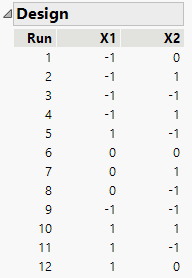

Figure 5.39 D-Optimal Design

In this D-optimal design, run 6 is the only run at the center point. D-optimal designs tend to place more runs at the extremes of the design space than do I-optimal designs. Recall that the I-optimal design had four center runs.

6. Click Make Table and then save as DOptDesign.

Compare Designs

1. Click on your IOptDesign table to make it your active table.

2. Select DOE > Design Diagnostics > Compare Designs.

3. Select DOptDesign to compare to the IOptDesgin and click OK.

4. Scroll to the prediction variance profiles.

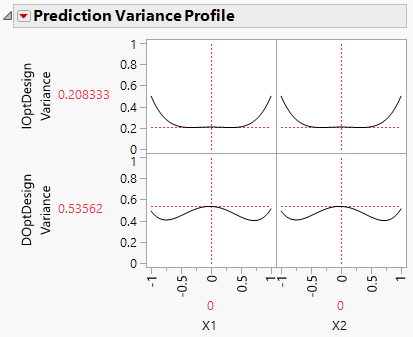

Figure 5.40 Prediction Variance Profile Comparison

At the center of the design region, the relative prediction variance is 0.53562, as compared to 0.208333 for the I-optimal design. This means that the relative standard error is 0.732 for the D-optimal design and 0.456 for the I-optimal design. All else being equal, at the center of the design region, confidence intervals for the expected response based on the D-optimal design are about 60% wider than those based on the I-optimal design.

The Design section shows that the D-optimal design has nine design points, one for every combination of X1 and X2 set to -1, 0, 1. The D-optimality criterion attempts to keep the relative prediction variance low at each of these design points. Explore the variance at the extremes of the design region by moving the sliders for X1 and X2 to -1 and 1. Note that the variance at these extreme points is usually smaller than the variance for the I-optimal design at these points.

5. Scroll to the fraction of design space plot.

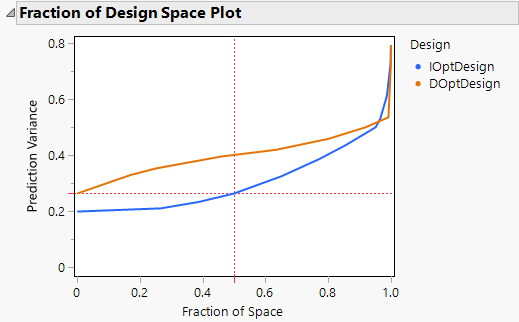

Figure 5.41 Fraction of Design Space Plot

The red cross-hairs in each plot indicate the maximum prediction variance for 50% of the design space. For 50% of the design space, the prediction variance for the I-optimal design falls below about 0.27. For the D-optimal design, the prediction variance is about 0.4.

The variance curve for the I-optimal design is below the curve for the D-optimal design over at least 90% of the design space. This reflects the fact that I-optimality attempts to minimize prediction variance over all of the design space. In contrast, D-optimality focuses on better estimation of the model terms.