Example of an Accelerated Life Test Design

Use the Accelerated Life Test Design platform to create an accelerated life test design for one accelerating factor.

1. Select DOE > Special Purpose > Accelerated Life Test Design.

Notice that One accelerating factor is selected by default.

2. Under Factor Name, click X1 and type Temperature.

Notice that the Number of Levels is set to 3 by default.

3. Notice that the Factor Transformation is set to Arrhenius Celsius.

4. Enter 10 for both the Low Usage Condition and the High Usage Condition.

Setting both the low and high usage conditions to 10 indicates that 10 is the normal usage condition.

5. Enter 40 for the Low Test Condition and 80 for the High Test Condition.

6. Click Continue.

Use subject matter knowledge to specify the life distribution model (LogNormal or Weibull), the parameters to estimate, and initial estimates of the acceleration parameters.

7. Specify a Weibull distribution.

8. Select Specify Quantile to enter the priors for the acceleration factor, the expected failure proportion at a given time, and value for the acceleration factor. This information is used to calculate the intercept.

9. Accept the default values for activation energy and 1/β.

From prior experiments, you expect 90% of units to fail by 720 hours at the high test condition.

10. Set Expected failure proportion to 0.9.

11. Set At time to 720, or about one month.

12. Set At Temperature to 80.

13. Click Continue.

14. From the Accelerated Life Test Plan red triangle select ALT Optimality Criterion > Make Failure Probability Optimal.

15. Set Time range of interest to 9000 to 17,000 or about 1 to 2 years.

16. Leave the Monitoring Type set to Continuous Monitoring.

17. Set the Total number of units under test to 200.

18. Set Length of test to 720 for a 30-day test.

19. Click Make Design.

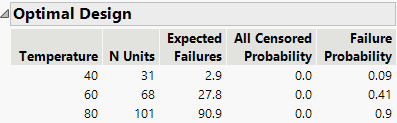

The optimal design allocates 31 units to the low temperature, 68 to the medium temperature, and 101 units to the high temperature.

Figure 23.2 Optimal Design

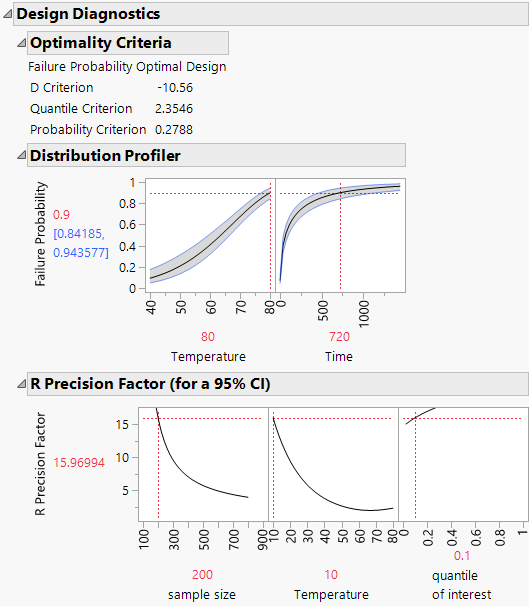

Use the design diagnostics to evaluate your design prior to running your life test.

Figure 23.3 Design Diagnostics

The distribution profiler gives the expected failure probability. The profiler is set at temperature of 80 and time of 720, the settings for the design. Explore how changes to your design impact the failure probability estimation. The size of the intervals around the estimates gives a sense of the anticipated level of uncertainty for your test plan.

The R Precision Factor profiler gives the value of the metric for the temperature factor and quantile over a range of sample sizes. This gives you a sense of the anticipated uncertainty from the life test in relation to the number of samples on test. If you were able to increase your number of test units from 200 to 400 you could decrease the R precision factor.

Build an Accelerated Life Test Design

Build an ALT design by selecting DOE > Special Purpose > Accelerated Life Test Design.

The ALT Plan updates as you specify and review the design.

• Specify the ALT Acceleration Factors

• Review and Update Specifications for ALT Plans

• Create and Assess the ALT Design

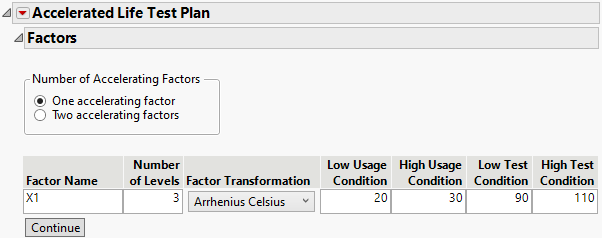

Specify the ALT Acceleration Factors

The first step for an accelerated life test (ALT) design is to define the accelerating factors and design type.

Figure 23.4 Initial ALT Test Plan Window

Number of accelerating Factors

One accelerating factor

Select for a design with one factor.

Two accelerating factors

Select for a design with two factors.

Include interaction term

(Available only for two factor models.) Select to include interaction term.

Factor Name

Enter a name for each acceleration factor.

Number of Levels

For each acceleration factor, enter the number of levels to include in the experiment.

Factor Transformation

For each acceleration factor, select a transformation function. This transformation describes the life-stress relationship, which is the manner in which the life distribution changes across stress levels. The transformations available are Arrhenius Celsius, Reciprocal, Log, Square Root, and Linear.

Low Usage Condition

For each acceleration factor, enter a lower bound for its value in typical usage conditions.

High Usage Condition

For each acceleration factor, enter an upper bound for its value in typical usage conditions.

Note: The Low Usage Condition and High Usage Condition values can be equal. Use equal values when the usage condition is a single value.

Low Test Condition

For each acceleration factor, enter the low test condition.

Additional Examples of Accelerated Life Test Designs

• Example of Estimating Priors for an Accelerated Life Test Design

• Example of Augmenting an Accelerated Life Test Design

Example of Estimating Priors for an Accelerated Life Test Design

In this example, you construct a failure probability optimal ALT test design for a mechanical component. The single acceleration factor is torque, and the normal use stress is 35 Nm (newton meters). You want to estimate the time at which 10% of the units fail at the normal use stress. You construct a failure probability optimal ALT test.

Your test plan has the following characteristics:

• A total of 100 units are available for testing.

• The life distribution is assumed to be Weibull.

• The life-stress relationship is given by the logarithmic transformation.

• You plan to test torque at three stress levels: 50, 75, and 100 Nm.

• You have prior knowledge to predict initial failure times at the test levels. See Obtain Prior Estimates.

• The test runs for 5,000 cycles.

• You will monitor the process for failures on a continuous basis.

Obtain Prior Estimates

To create an accelerated life test design, you must provide prior estimates of the parameters. Here is an approach to obtaining prior estimates:

1. Use your process knowledge to create a table of hypothetical, but likely, failure times at a small number of stress levels.

2. Use the Fit Life by X platform to fit a model and obtain estimates of the model parameters.

3. Use these estimates as your prior values for creating a design using the ALT Design platform.

Follow the approach outlined above with a data table containing estimates of the number of failure cycles for a balanced design.

1. Select Help > Sample Data Folder and open Design Experiment/Torque Prior.jmp.

2. Select Analyze > Reliability and Survival > Fit Life by X.

3. Select Cycles and click Y, Time to Event.

4. Select Torque and click X.

5. From the Relationship list, select Log.

6. Enter 35 for the Use Condition. Recall that 35 Nm is the normal use condition.

7. From the Distribution list, select Weibull.

Figure 23.8 Fit Life by X Launch Window

8. Click OK.

9. Scroll down to the Weibull Results section and open the Correlation Matrix section.

Figure 23.9 Fit Life by X Model for Prior Data

The model for the mean is given in the Estimates section. The Estimate column contains the parameter estimates for the intercept (β0), the linear coefficient (β1), and the scale (σ). The standard errors column contains the standard errors for the estimates. The estimated correlations for the parameter estimates are given in the Correlation Matrix section. Use these parameter estimates, standard errors, and correlations as your prior values to construct your ALT design.

Enter Basic ALT Design Specifications

Use the estimated priors to create the accelerated life test design.

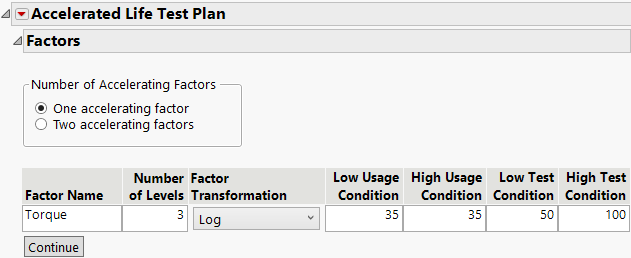

1. Select DOE > Special Purpose > Accelerated Life Test Design.

Notice that One accelerating factor is selected by default.

2. Under Factor Name, click X1 and type Torque.

Notice that the Number of Levels is set to 3 by default.

3. Select Log under Factor Transformation.

4. Enter 35 for both the Low Usage Condition and the High Usage Condition.

Setting both the low and high usage conditions to 35 indicates that 35 is the normal usage condition.

5. Enter 50 for the Low Test Condition and 100 for the High Test Condition.

Figure 23.10 Completed ALT Specification Window

6. Click Continue.

Enter Prior Specifications

1. Click the Accelerated Life Test Plan red triangle and select ALT Optimality Criterion > Make Failure Probability Optimal.

2. Ensure that Weibull is selected as the Distribution Choice.

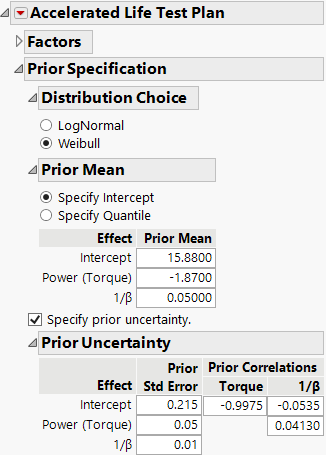

1. Under Prior Mean, select Specify Intercept and enter the prior acceleration model parameter estimates that you obtained using the Fit Life by X platform with your hypothetical data:

– Enter 15.88 for Intercept.

– Enter -1.87 for Power (Torque).

– Enter 0.05 for 1/β (scale parameter for a Weibull model).

2. Select Specify prior uncertainty.

3. Enter the estimated standard errors and correlations from the prior acceleration model. Figure 23.11 shows the completed Prior Uncertainty section:

Figure 23.11 Completed Prior Specifications

4. Click Continue.

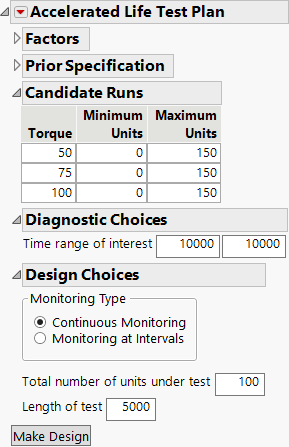

Notice the Torque Level Values are set to 50, 75, and 100.

Note: JMP sets the values of the levels evenly spaced between the low and high test conditions. You can change the levels.

You plan to conduct the test over 5,000 cycles. You are interested in predictions for as many as 10,000 cycles.

5. In the Diagnostic Choices section, enter 10,000 for both boxes for Time range of interest.

6. In the Design Choices section, ensure that Continuous Monitoring is selected as the Monitoring Type.

7. Enter 100 for the Total number of units under test.

8. Enter 5,000 for Length of test.

Figure 23.12 Completed Diagnostic and Design Choices