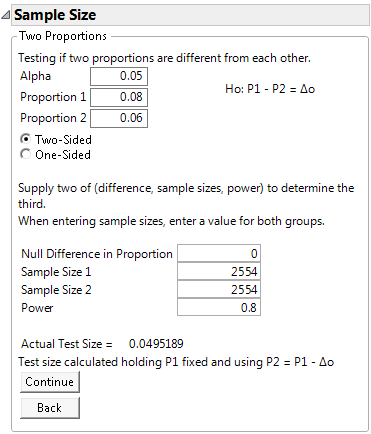

Example of the Two Sample Proportions Calculator

Suppose you are responsible for two silicon wafer assembly lines. Based on the knowledge from many runs, one of the assembly lines has a defect rate of 8% and the other line has a defect rate of 6%. You want to know the sample size necessary to have 80% power to conclude there is a difference in defect rates.

1. Select DOE > Design Diagnostics > Sample Size and Power.

2. Click Two Sample Proportions.

3. Leave Alpha set at 0.05.

4. Enter 0.08 for Proportion 1.

5. Enter 0.06 for Proportion 2.

6. Select a Two-Sided test.

7. Enter 0 for Null Difference in Proportion.

8. Leave Sample Size 1 and Sample Size 2 blank.

9. Enter 0.8 for Power.

10. Click Continue.

Figure 17.13 Difference between Two Proportions for a Two-Sided Test

The calculator shows that you should test a sample size of 2,554 wafers from each production line in order to detect a difference in defect rates.