Example of a Multivariate Control Chart

This example illustrates constructing a control chart for data that are not sub-grouped. The data are measurements on a steam turbine engine. For an example that uses sub-grouped data, Example of Monitoring a Process Using Sub-Grouped Data.

Step 1: Determine Whether the Process Is Stable

1. Select Help > Sample Data Library and open Quality Control/Steam Turbine Historical.jmp.

2. Select Analyze > Quality and Process > Control Chart > Multivariate Control Chart.

3. Select all of the columns and click Y, Columns.

4. Click OK.

Figure 10.2 Initial Multivariate Control Chart

The process seems to be in reasonable statistical control, because there is only one out-of-control point. Therefore, it is appropriate to create targets based on this data.

Step 2: Save Target Statistics

1. Click the red triangle next to Multivariate Control Chart and select Save Target Statistics.

This creates a new data table containing target statistics for the process.

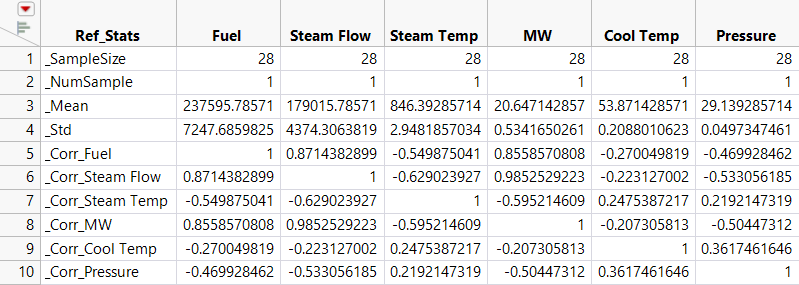

Figure 10.3 Target Statistics for Steam Turbine Data

2. Save the new data table as Steam Turbine Targets.jmp.

Now that target statistics have been established, create the multivariate control chart that monitors the process.

Step 3: Monitor the Process

1. Select Help > Sample Data Library and open Quality Control/Steam Turbine Current.jmp.

This sample data table contains recent observations from the process.

2. Select Analyze > Quality and Process > Control Chart > Multivariate Control Chart.

3. Select all of the columns and click Y, Columns.

4. Click Get Targets.

5. Open the Steam Turbine Targets.jmp table that you saved.

6. Click OK.

The default alpha level is set to 0.05. Change it to 0.001.

7. Click the red triangle next to Multivariate Control Chart and select Set Alpha Level > Other.

8. Type 0.001 and click OK.

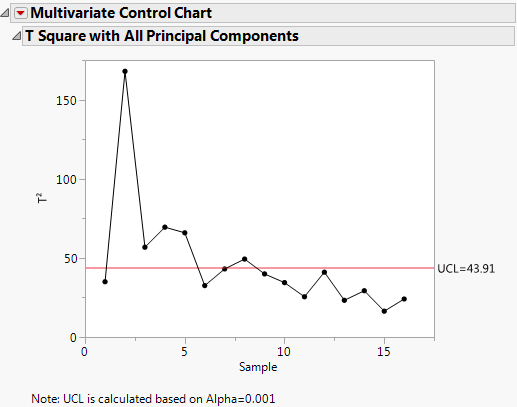

Figure 10.4 Steam Turbine Control Chart

Figure 10.4 shows out-of-control conditions occurring at observations 2, 3, 4, 5, and 8. This result implies that these observations do not conform to the historical data from Steam Turbine Historical.jmp, and that the process should be further investigated. To find an assignable cause, you might want to examine individual univariate control charts or perform another univariate procedure.