Are you a:

Yield / Process Integration Engineer in wafer fab?

Formulation Scientist in drug tablet production?

Chemist in formulation development?

Engineer in refinery process?

Scientist in food manufacturing?

Quality Control Engineer maintaining high output standards?

Do you manage hundreds or thousands of key process parameters, and have a large number of parameters under your monitoring and control?

Do you still receive failure analysis request (FAR) or customer complaints/returns even if you have an existing Six Sigma process at 3.4 defective PPM?

Are you at risk of return rates months or years after product delivery?

Are you lacking manpower / time / resources?

All these indicate an existing and undetected problem in your production line. With high correlation among process parameters (multicollinearity), your standard modelling method cannot identify critical process parameters for continuous improvement (CI).

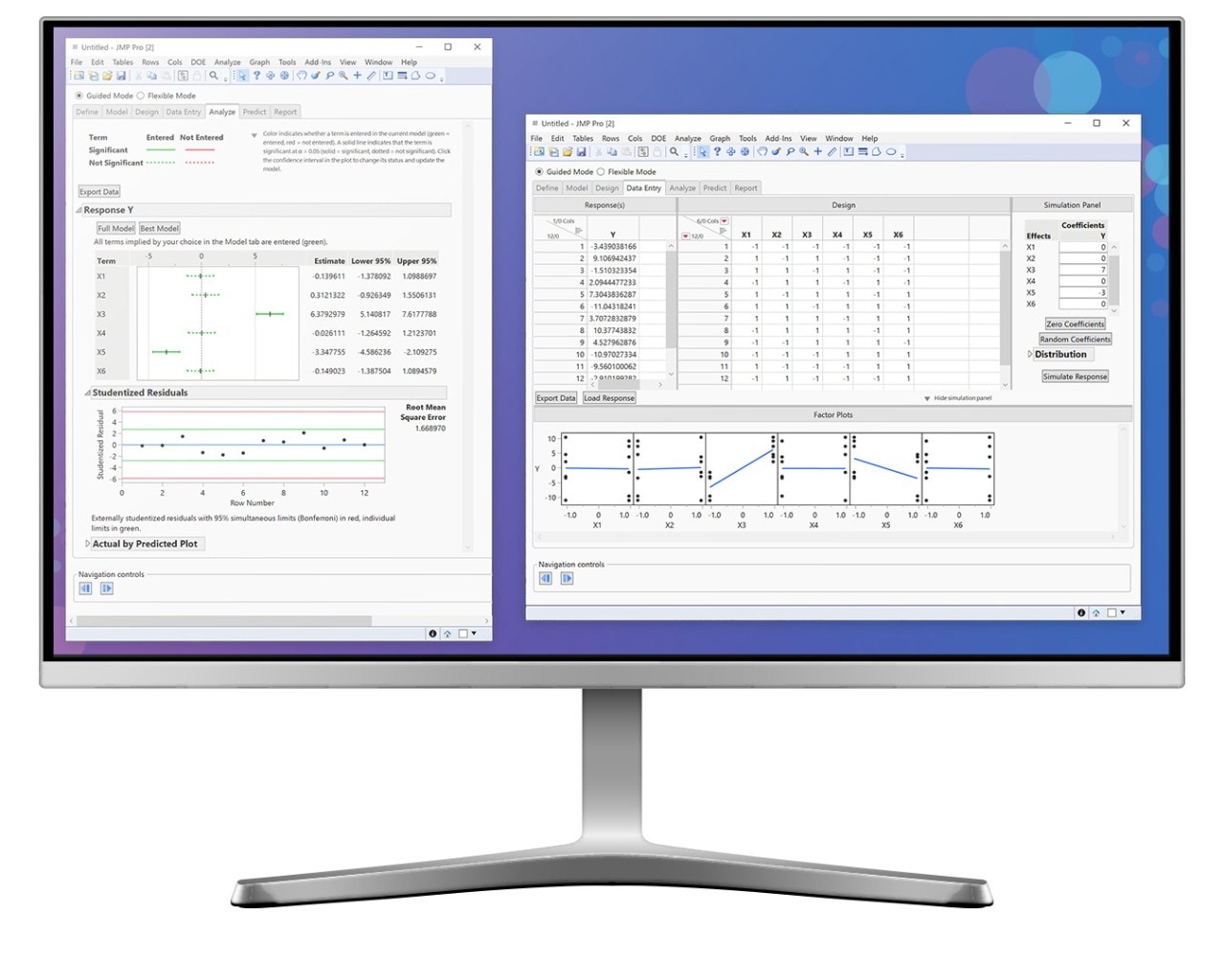

In this on-demand webinar, you can solve this nightmare with JMP using:

- Principal Components Analysis (PCA)

- Model Driven Multivariate Control Chart (MDMCC)

- Partial Least Squares (PLS) in JMP Pro

Register to watch this on-demand webinar to handle multicollinearity in your data using the power of JMP.

Want to learn more about JMP? Send your enquiry to jmpasia@jmp.com.